The principle of TONZON Thermosheets

.An insulating dry liner is constructed using layers of TONZON Thermosheet foil. The foils are hung 2 cm apart, creating layers of motionless air between them. The combination of the film and motionless air provides good insulation. The advantage of this system is that the depth of the air layer is up to you and can be increased in increments of 2 cm. Of course, the thicker the insulation layer, the better the insulation value will be.

The thickness of the insulation layer is often based on the insulation value you want to achieve. Of course, this can also be done the other way round. To achieve a recommended Rd = 3.5, you need 5 layers of air and thus 10 cm.

Making a dry liner

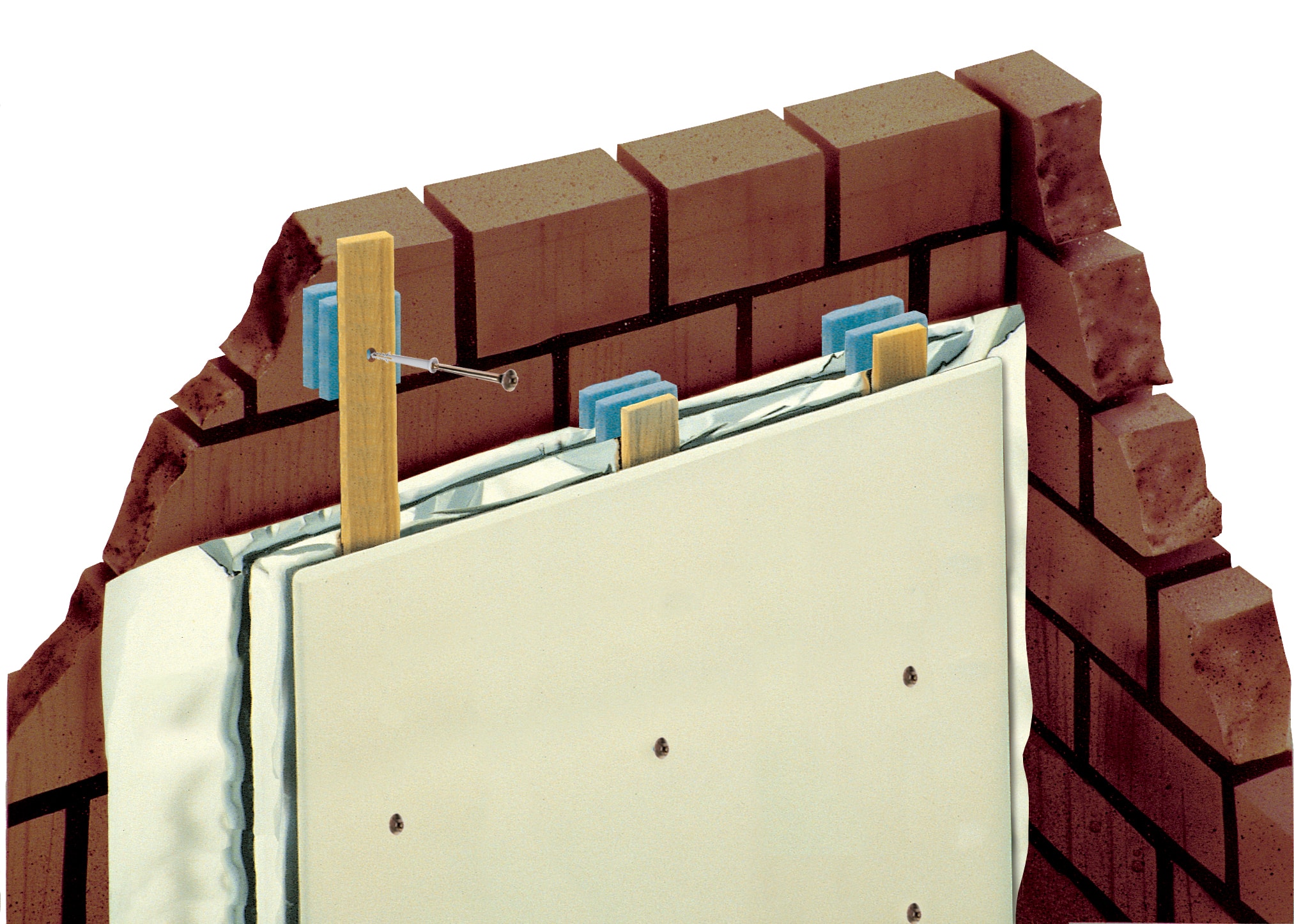

Thermosheets are used to make an insulated dry liner with TONZON. The sheets are spaced 2 cm apart, using a framework of battens and XPS blocks (as cold bridge breakers). The image shows how this is built. If only battens are used, some of the heat can still escape through the wood. So the slats are alternated with XPS blocks, ideally using 2 layers of XPS per wooden beam. Not only does this increase the insulation value, it also requires less material.

See how to make your own dry liner with TONZON Thermosheets.

Soundproofing

Because the Thermosheets cover the entire wall and contain motionless air, noise transmission through the wall is significantly reduced. The best effect can be achieved by placing the wooden battens on rubber or felt. Separating the dry liner from the floor and roof in this way creates a soundproof structure. Dry liners with TONZON are therefore suitable for reducing noise from outside, such as from busy roads.

Finishing

For finishing, boards will be mounted on the last layer of battens. Plasterboard is often used for this purpose. The downside is that such boards cannot support anything. Sometimes, for this reason, a layer of tempex is mounted before placing the plasterboard. In most cases, the next step is a layer of plaster. A cheaper alternative is to wallpaper the plasterboard.